'Product Blog'

Chlorine-free titanium ALD precursor for leading edge semiconductor applications

TDMAT ALD precursor is an attractive alternative to TiCl4

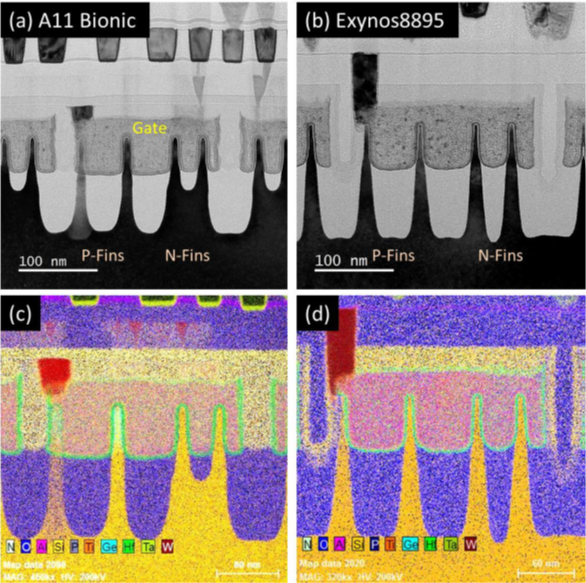

Atomic layer deposition (ALD) of titanium-based compounds has been a crucial process step in the modern semiconductor industry. Titanium nitride (TiN), due to its high electrical conductivity, has been in use as an inorganic anti-reflective coating for lithography, hard-mask for low-κ patterning, transistor gate electrodes, and diffusion barrier for tungsten contacts and Cu interconnects. Intel, in its 10nm, 3rd generation FinFET based technology node, employs a conformal Ti layer to wrap around source/drain diffusion regions to lower the spreading resistance (Link). Apple’s A11 bionic processor chip based on TSMC’s 10nm technology and Samsung’s Exynos 8895 processor chip based on its 10nm technology also incorporates Ti-based liners for tungsten contacts (Link). Globalfoundries and IBM Research investigated cobalt as a replacement of tungsten in the contacts for advanced semiconductor chips, and this process also incorporated a TiN barrier and a Ti liner (Link). TiN electrodes have also been promising for ferroelectric memory applications.

Figure 1: Cross-section, perpendicular to the fin direction, TEM images on the 6T-SRAM area for (a) A11 and (b) Exynos8895. Images (c) and (d) are corresponding EDS mappings of (a) and (b), respectively. (Picture credit: MSSCORPS CO., LTD.)

Titanium dioxide (TiO2) is also an attractive candidate for several thin-film applications, such as high-k material for electronic devices, anti-reflection optical coatings, biocompatible coatings, photocatalysis, and solar cells. Besides, TiO2 is also a constituent of several crucial multi-metal oxide systems, such as strontium titanates (STOs), barium strontium titanates (BSTs), and lead zirconium titanates (PZTs), for dielectric and ferroelectric applications.

The TiCl4 precursor has been widely used to deposit Ti-based thin-films. However, due to severe Cl contamination, low growth per cycle, the corrosive nature of the reaction by-product (mainly HCl), high process temperature, and lower reactivity of TiCl4, the industry switch over to metal-organic precursors is swiftly gaining traction.

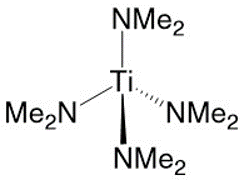

We offer a vast variety of metal-organic precursors for depositing superior Ti-based thin-films in semiconductor as well as non-semiconductor applications. TDMAT [tetrakis(dimethylamino)titanium(IV)] (Product Catalog Number: 93-2240, CAS Number: 3275-24-9) is one of the most preferred high-purity metal-organic precursors in our chemical offering. Highly volatile and reactive TDMAT offers adequate vapor pressure even at room temperature and enables low temperature (< 140°C) deposition of high-quality Ti-based thin-films.

Figure 2: TDMAT molecule

For more than fifty years, we’ve been manufacturing inorganic and organometallic chemicals which has led us to expand our product offering of MOCVD, CVD and ALD precursors. We are continually adding new products for this dynamic and exciting field. Our product range includes:

Metal alkyls

Metal alkylamides

Metal amidinates

Metal alkoxides

Metal β-diketonates

Metal cyclopentadienyls

Metal halides

Volatile organometallics

Volatile metal carbonyls

Electronic grade chemicals

Single source precursors for mixed metal oxides

Product mentioned in this blog:

93-2240: Tetrakis(dimethylamino)titanium(IV), 99% TDMAT (3275-24-9)

Related Product Lines & Resources:

CVD & ALD Precursors

MOCVD, CVD & ALD Precursors Booklet

See full Material Science product line

*This blog had been researched, produced and written by Jonas Sundqvist. It is reposted from BALD Engineering's blog on January 25, 2020. Original blog: https://www.blog.baldengineering.com/2020/01/chlorine-free-titanium-ald-precursor.html